Functions and benefits realized:

- Remote power on / off of devices. The system controls who can work with the devices and when, and only then the device is activated. This allows you to allocate unit operating time to the production of specific parts, eliminate unauthorized use of the equipment (not for business), and analyze employee performance (to minimize downtime).

- Remote measurement of process parameters (power, current or other). This allows you to control their compliance with technological requirements, automatically report deviations, and alert you to potential failures

- Remote power consumption measurement and employee registration allow you to assign power consumption to a specific project or process, thus purifying their cost

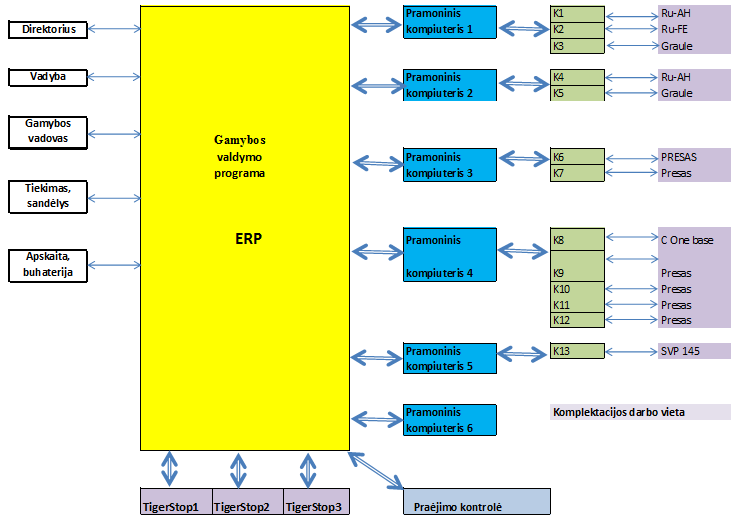

These solutions perfectly complement the functionality of a modern production management program (ERP) and provide the control of production equipment through workstation-based industrial computers and specialized controllers.

The algorithm is as follows:

- ERP prepares work tasks and transfers them to workstation computers

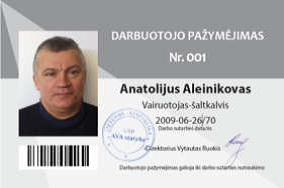

- The employee selects the job scheduled on the computer and executes it by holding the employee certificate on the computer.

- The computer sends a command to the devices to start the operation, sends the message “Employee XYZ has run operation on the ABC machine KLN” to the ERP

- The computer checks that the machine is on and running. If not working, generates an audiovisual message to the employee, transmits it to the ERP.

- When the machine is finished, it records the time spent on the e-mails. power, transmits info to ERP.

- Power consumption curve additionally analyzed compared to normal in normal operation (excessive deviation may be a sign of impending failure)

- Next, the employee selects another job on the computer and executes it, holding the employee’s certificate on the computer, the algorithm repeats from 4 p.m.

Employee identification is used to identify employees. contactless cards, which at the same time provide access control to the company and automatic table formation.

This will allow the quality control system to record at any time any manufacturing operations performed. This gives an economic analysis of the real duration of the production operations and calculates the salary of the employees.